TORQUE GUN PM MANAGEMENT

Precision Tools. Expert Support. Proven Results.

Power Your Production with Total Torque Management Expert On-Site Support. Maximum Uptime. Lower Costs.

Elevate your production performance with Total Torque Gun Management — a complete on-site solution designed to eliminate downtime, boost throughput, and maximize your investment.

Why Total Torque Gun Management?

Zero Unplanned Downtime

Torque guns are reliable, performance-ready, and eliminate unexpected failures.

Higher Throughput

Keep production on pace with tools that work exactly when needed.

Reduced Capital Expenses

Fewer new gun purchases and extended tool life save you money.

No Repair Shipping Delays

On-site repairs provide fast turnaround, cutting costly downtime.

Lean, Streamlined Inventory

Lower your spare parts inventory with better management and planning.

Certified, Reliable Refurbishment

Professionally restored torque guns deliver consistent, trouble-free operation.

Digital Tracking and Performance Analytics

Monitor every tool’s performance, maintenance history, and service needs.

Standardized Equipment and Spare Parts

Simplify operations and drive efficiency across production lines.

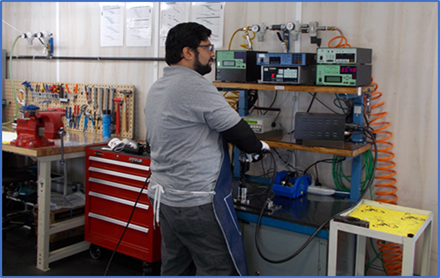

Fast, Professional On-Site Support

Our expert team delivers immediate assistance to keep your operations seamless.

Significant Cost Savings

Our program typically reduces torque gun management costs by 20–30% compared to current practices.

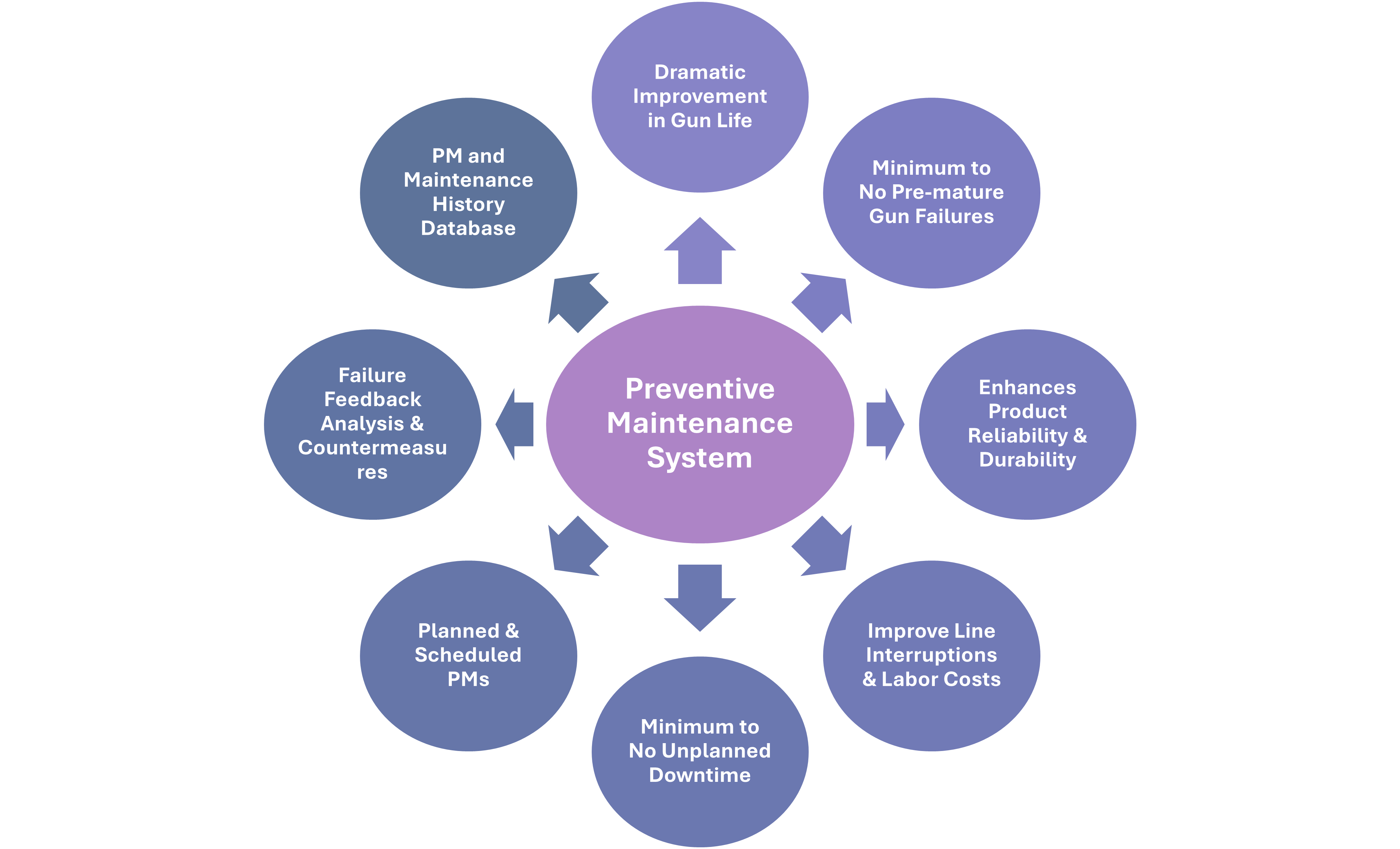

Key Components of Our System

Torque Gun Specification & PM Scheduling

Standardize equipment and proactively maintain peak performance.

Digital Setup and Tracking

Get complete visibility into tool health, service schedules, and performance.

Project Management & Communication Framework

Structured, transparent communication ensures smooth execution and quick results.

Asset Identification & Line Crawl Verification

Accurately validate every torque gun asset to ensure readiness and compliance.

In-House Setup for Tools, Spare Parts, and Workflows

Tailored organization for faster repairs, replenishment, and tracking.

Scalable Rollout Across All Manufacturing Areas

Expand coverage seamlessly as your needs grow.

KPI Tracking and Power BI Reporting

Gain actionable insights into uptime, failures, repair trends, and overall program success.

Experience the Total Torque Difference — Launch Your Program Today by Giving Us a Call.